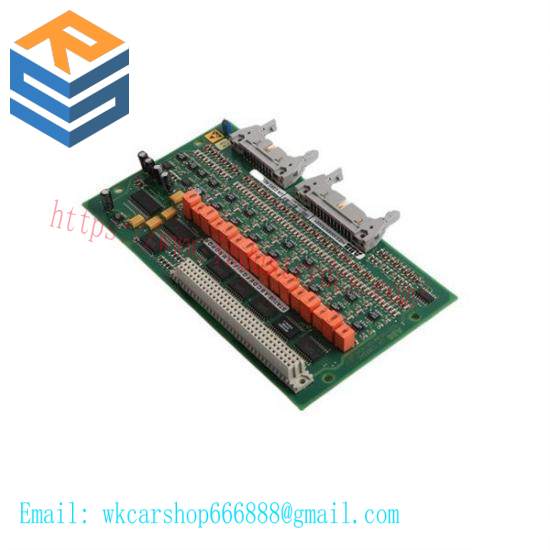

Module Positioning: This component is the core control unit in the ABB PCS6000 system. It is an intelligent controller/input/output module (such as the UFC765AE102 model) and also functions as a printed circuit board (PCB). Its official part number is 3BHE003604R0102. It is widely used in industrial automation, power conversion, and excitation systems.

Key Parameters:

Electrical Characteristics: Input voltage 220V, output 24V DC, supports wide-range logic processing (such as true/false values and numerical range control), current 60mA, output frequency 45Hz.

Environmental Adaptability: Operating temperature range -40°C to 80°C (some models support -40°C to 85°C), IP65 protection, dust and water resistance, suitable for harsh industrial environments.

Physical Specifications: Dimensions are approximately 132mm × 105mm × 52mm (or 150mm × 100mm × 52mm, depending on the source), weighing approximately 800g. It features a reinforced corrugated aluminum chassis and supports 35mm DIN rail mounting.

Communication Capabilities: Compatible with industrial protocols such as Modbus, PROFINET, and IEC 61850, and supports Ethernet, RS485/RS232 interfaces. It seamlessly integrates with ABB ACS6000/ACS800 drives, PLCs (such as the S7-1500), and DCS systems.

Functionality and System Integration

Core Functions:

Ground Fault Monitoring: As a core component of the PCS6000 system’s ground protection, it monitors neutral-to-ground voltage, insulation resistance, and leakage current in real time. It uses closed-loop current detection to identify the fault location and severity, triggering threshold protection.

Control and Regulation: Integrated Pulse Trigger Board (PTB) functionality generates thyristor/IGBT trigger signals to control the rectifier bridge output; supports PID algorithms for generator excitation current regulation, voltage stabilization, and reactive power control.

System Protection: Real-time monitoring of generator voltage, current, excitation current, and other parameters, with overvoltage, undervoltage, and overcurrent protection to prevent equipment damage.

System Integration:

Compatibility: Compatible with ABB UNITROL 6000 excitation systems, ACS6000/ACS800 inverters, PLCs, and DCS systems, supporting modular expansion and redundant configurations (such as dual processors and dual power modules).

Application Scenarios: Widely used in wind power/photovoltaic inverter protection, grid ground fault monitoring, power station equipment monitoring, industrial automation production lines (such as assembly lines and processing equipment), motor drives, and pump equipment control.

Installation and Maintenance Guide

Installation Specifications:

Wiring Requirements: Keep weak and strong current signal lines separate. Use yellow-green insulated copper core flexible wire with a cross-sectional area of no less than 4 mm². Ensure the ground terminal is securely connected to prevent electromagnetic interference.

Environmental Management: The installation environment must be free of dust and corrosive gases, with good ventilation and heat dissipation to prevent performance degradation caused by high temperatures. The base channel steel must be securely welded to the protective conductor (such as galvanized flat steel) and painted with anti-rust paint.

Maintenance Key Points:

Daily Inspection: Regularly tighten the terminal blocks, clean the fiber optic connector, and calibrate the zero drift and span adjustment using ABB system tools.

Troubleshooting:

Common Problems: False alarms (such as three-phase imbalance or starting current surge), communication interruption, and insulation failure.

Handling Procedure: Hardware inspection (check the appearance and internal components after powering off), software diagnostics (read fault codes and analyze logs), and professional support.

Industry Certifications and Advantages

Certification Standards: Complies with international standards such as IEC 61800-5, CE, and UL, and has passed electromagnetic compatibility certification (e.g., ESD ±8kV, surge ±2kV), ensuring compliance for applications in industries such as power, petrochemicals, and metallurgy.

Core Advantages:

High Reliability: IP65 protection and a wide operating temperature range make it suitable for harsh industrial environments; redundant design supports hot swapping, minimizing downtime.

Precise Monitoring: Millisecond-level response speed accurately identifies even minor ground faults; customizable control logic and parameter settings are supported to meet diverse operational requirements.

Strong Scalability: Modular design enables rapid integration and expansion, and compatibility with multiple industrial protocols adapts to system sizes of varying sizes.

Summary

As the core control unit of ABB’s PCS6000 system, the UF C765 AE102 provides a solid foundation for the safe operation of industrial equipment with its high-precision monitoring, strong environmental adaptability, and system integration capabilities. Daily maintenance requires attention to wiring specifications and environmental management. Troubleshooting should combine hardware inspection and software diagnosis, and professional support should be sought when necessary to ensure system stability. The module’s widespread application in wind power, manufacturing, energy, and other fields has proven its reliability and cost-effectiveness in complex industrial scenarios.

Related products to submit:

3BHE019719R0101

5SHY3545L0016

3BHB020720R0002

5SDF1045H0002

3BHE019719R0101

3BHB020720R0002

5SHY3545L0016

5SHY3545L0016 3BHE019719R0101

5SHY3545L0016 3BHE019719R0101

81943A041-1

3BSE018876R1

PFSK151 3BSE018876R1

More…

There are no reviews yet.