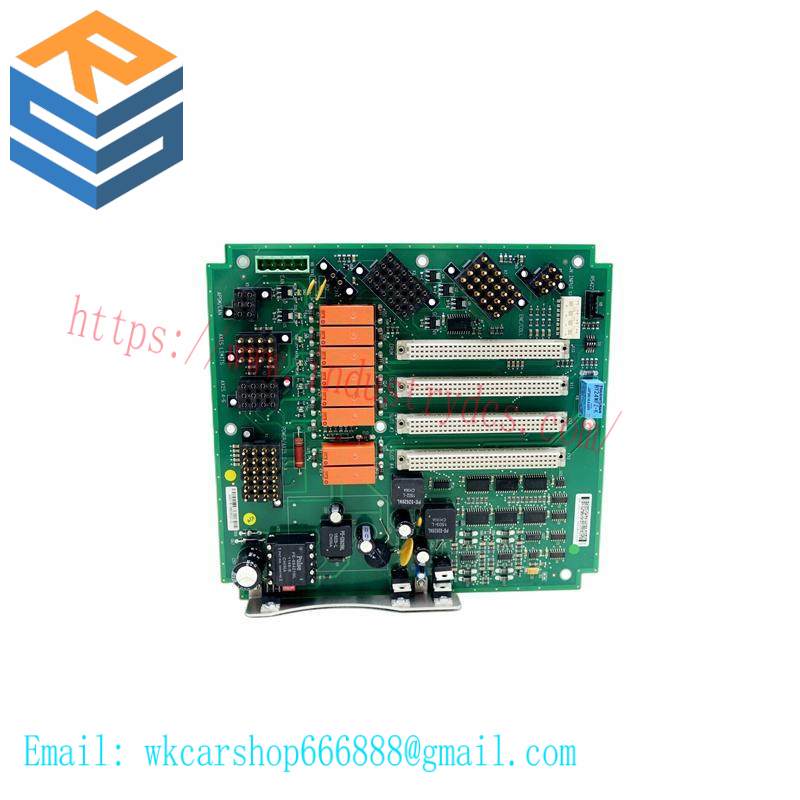

The ICST08A9 is a high-performance programmable logic controller (PLC) from the Swiss ABB Group and a core component of ABB’s high-end control platform. Designed for complex industrial automation applications, it is widely used in process control, discrete manufacturing, and infrastructure.

Core Functions and Features

1. Control and Computing Capabilities

Core Functions:

Executes control programs, data processing, logical operations, and system communication management.

Supports multitasking, enabling simultaneous execution of multiple control tasks to improve system efficiency.

Processor:

Utilizes a high-performance RISC processor, ensuring fast response and precise control, with a minimum scan cycle of up to 0.2 milliseconds (the specific value depends on application complexity).

2. Modular Design

Scalability:

Supports seamless integration with ABB I/O modules (such as DI/DO, AI/AO), communication modules (PROFIBUS DP, PROFINET, EtherCAT), and power modules.

Builds distributed control systems (DCS) or PLC systems to meet automation needs of varying scale and complexity.

Mounting Method:

Din-rail mounting for easy integration into existing industrial control cabinets.

3. Communication and Interfaces

Communication Protocols:

Ethernet Interface: Supports industrial Ethernet protocols such as PROFINET, EtherNet/IP, and Modbus TCP/IP.

Serial Interface: RS-485 for connecting field instruments and devices.

Network Configuration:

Supports high-speed data exchange, facilitating integration with higher-level systems (such as SCADA and MES).

4. Reliability and Environmental Adaptability

Operating Environment:

Operating temperature range: -20°C to +70°C, suitable for harsh industrial environments.

Power Supply: 24V DC, ensuring stable operation.

Reliability:

Uses high-quality electronic components, offering high anti-interference capabilities and long-term stability.

Hot-swappable functionality facilitates maintenance and module replacement.

Application Areas

1. Process Industries

Typical Applications:

Precise control of complex production processes in industries such as petrochemicals, pharmaceuticals, and food and beverages.

Enables process parameter adjustment, equipment linkage, and safety interlocks.

2. Discrete Manufacturing

Typical Applications:

Control of production lines, robots, and automated equipment in the automotive, electronics assembly, and packaging industries.

Supports high-speed motion control, path planning, and quality inspection.

3. Infrastructure and Energy

Typical Applications:

Automated equipment control and intelligent system management in power generation, water treatment, metallurgy, and building materials.

Used in distributed energy systems, smart grids, and environmental protection projects.

ABB PLC Product Line Comparison

Features: AC500 Series, AC800M Series

Applicable Scenarios: Small and medium-sized automation (e.g., packaging, building engineering) and large industrial projects (e.g., power generation, petrochemical engineering)

Modular design supports basic I/O expansion, highly modular, and supports redundant configurations

Programming Software: Automation Builder Control Builder M (integrated with 800xA)

Typical Applications: Motor control, simple logic operations, complex process control, and distributed systems

Supporting Software and Resources

1. Programming and Configuration Software

Automation Builder:

ABB’s integrated development environment supports PLC programming, HMI design, and system configuration.

Control Builder:

Designed for writing, debugging, and diagnostics PLC programs, supporting IEC 61131-3 standard languages (e.g., LD, ST, and FBD).

2. Technical Support and Services

Quality Assurance:

ABB provides a one-year warranty and supports firmware and software updates.

Technical Documentation:

Users can download product manuals, wiring diagrams, and installation guides from the ABB official website.

Operation and Maintenance Guide

Hardware Configuration Steps

Step 1: Create a new project in ABB programming software and select the corresponding PLC series (e.g., AC500).

Step 2: Add a module (e.g., CPU, DI/DO) and enter the serial number ICST08A9 to bind the hardware.

Step 3: Configure I/O addresses, communication parameters, and network settings.

Troubleshooting

Communication interruption: Check the network cable, IP address, and firewall settings.

Module not recognized: Confirm that the serial number matches the software library or update the firmware.

Power supply abnormality: Measure the module supply voltage and check the fuse or power module.

Industry Trends and Expansion

With the advancement of Industry 4.0, ABB PLCs are developing in the following directions:

Edge computing integration: Embed AI algorithms in modules to enable local real-time decision-making.

Enhanced network security: Encrypted communications (such as TLS) and access control are used to defend against cyberattacks.

Improved energy efficiency: Dynamic power management reduces module standby power consumption.

Summary

The ICST08A9 is a high-performance, highly reliable programmable controller from ABB, suitable for a variety of industrial automation scenarios. Its modular design, high-speed computing capabilities, and extensive communication interfaces make it an ideal choice for building complex control systems.

Related product recommendations:

5SHY3545L0009 3BHE009681R0101

SC540 3BSE006096R1

SC510 3BSE003832R1

5SDF1045H0002

SC510 3BSE003832R1

3BHE040375R1023

PPD512A10-150000 3BHE040375R1023

3ASC25H219B DATX133

3ASC25H204 DAPU100

PPD113B03-26-100100 3BHE023584R2625

3ASC25H208 DATX100

REF542PLUS 1VCF752000

REF542PLUS 1VCR007346

More……

There are no reviews yet.