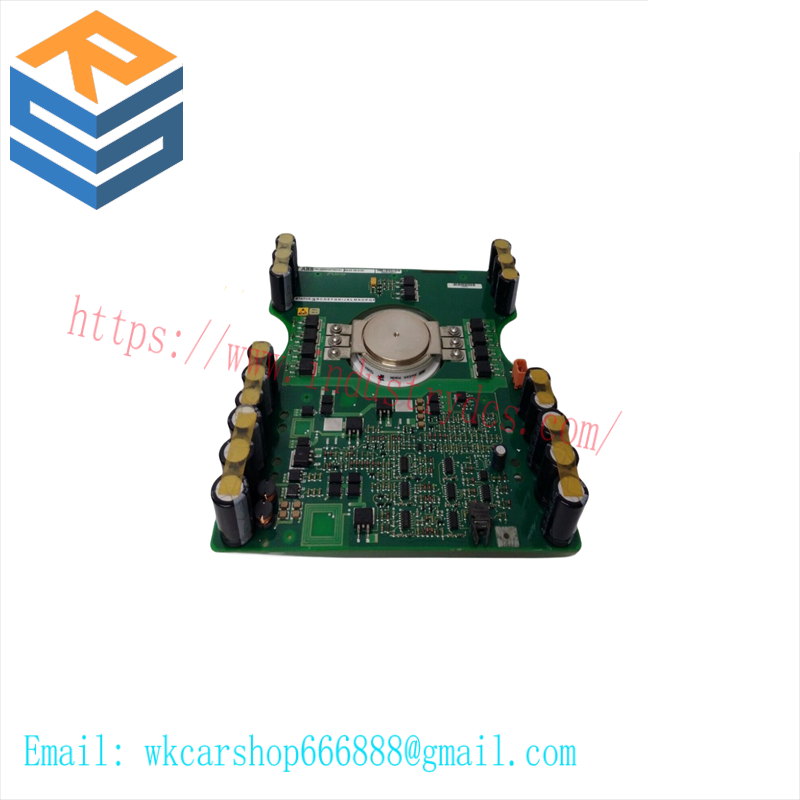

ACS6000 phase module S-097H 3BHB009885R0052 is a high-performance power electronic module produced by ABB. ACS6000 phase module S-097H 3BHB009885R0052 is mainly used in medium-voltage variable frequency drive systems. It undertakes rectification or inversion functions, converting the input AC power into DC power (rectification) or vice versa (inversion) to drive the motor. It integrates power semiconductor devices such as IGCT (integrated gate commutation thyristor) and has high reliability and high efficiency power conversion capabilities.

Product Overview

Product Name: ACS6000 Phase Module

Model: S-097H 3BHB009885R0052

Manufacturer: ABB

Application Field: Widely used in power, metallurgy, petrochemical, papermaking, mining and other industries to drive large motors and achieve precise speed and torque control.

Technical features

High reliability: The ACS6000 phase module adopts advanced power semiconductor devices such as IGCT (integrated gate commutated thyristor), which has extremely high reliability and stability, and can ensure the long-term stable operation of the inverter in harsh industrial environments.

Modular design: The phase module adopts modular design, which is easy to install, maintain and replace. This design not only improves the flexibility of the system, but also reduces maintenance costs and time.

High-performance control: The ACS6000 series inverter adopts advanced control technologies such as DTC (direct torque control), which can achieve extremely high torque and speed performance to meet the needs of various complex industrial applications.

Shared DC bus: Supports multi-drive operation and energy sharing, and improves the energy utilization efficiency of the system through the shared DC bus design.

Advanced control technology: With direct torque control (DTC) function, no encoder is required. Regardless of whether there is input voltage fluctuation or load mutation, it can always maintain the highest control accuracy, and can respond to transmission load and grid voltage changes or fluctuations at a very high speed.

Wide power range: The power range is 3.0 to 36.0 MW, and the input configuration has a variety of options such as 6-, 12- or 24-pulse diode rectifiers. There are also various specifications for input voltage, frequency and other parameters. The output power is 3000-36000 kW, the output voltage is 2.3, 3.3 kV, and the output frequency is 0-75 Hz. It can drive induction motors, synchronous motors and permanent magnet synchronous motors.

High efficiency and energy saving: The inverter efficiency is > 98%, and the motor speed can be adjusted according to actual needs to reduce energy consumption.

Good environmental adaptability: The enclosure protection level is standard IP32, and IP42 and IP54 are optional. It can operate at a certain altitude (0-2000 meters, higher under reduced capacity conditions), ambient air temperature (0-40 °C, higher under reduced capacity conditions) and external cooling water temperature (5-32 °C, higher under reduced capacity conditions), and the noise is < 75 dBA.

Function and role

Power conversion: The main function of the phase module is to convert DC power into AC power to provide the required power for the motor.

Speed and torque control: By accurately controlling the output voltage and frequency, the phase module can achieve precise control of the motor speed and torque to meet various needs of industrial production.

Protection function: The phase module also has multiple protection functions such as overcurrent, overvoltage, undervoltage, overheating, etc., which can ensure the safe operation of the motor and inverter.

Application scenario

Power industry: used for the generator excitation system of the power plant, reactive power compensation of the power grid, etc.

Metallurgical industry: used for the drive and control of large equipment such as rolling mills and continuous casting machines.

Petrochemical industry: used for variable frequency speed regulation of equipment such as pumps and compressors.

Papermaking industry: used for the transmission system of the paper machine to achieve precise speed and tension control.

Mining industry: used for the drive and control of equipment such as hoists and conveyors.

Maintenance and care

Regular inspection: Regularly inspect the phase module, including the appearance, connecting wires, heat sink, etc., to ensure that there is no damage or looseness.

Cleaning and maintenance: Regularly clean the heat sink and fan of the phase module to ensure good heat dissipation.

Troubleshooting: When a phase module fails, it should be promptly checked and repaired to avoid the expansion of the fault and affect the operation of the entire system.

Actual application case

SSAB Oxelosund blast furnace blower transformation: SSAB Oxelosund’s 6# blast furnace blower was originally driven by steam, and there were problems with turbine wear and reduced efficiency. By comparing the investment options, the ACS6000 variable frequency speed control system was selected. The system has the advantages of short investment payback period, high availability, application of existing blower equipment, short installation time, and low operation and maintenance costs. After adopting ACS6000, 16GW·h of energy can be saved each year, the output capacity is increased, and the equipment life is also extended.

NASA Wind Tunnel Project: ABB used the world’s largest 101MW inverter to transform a wind tunnel for NASA. The inverter was used in a 135,000hp (1hp = 745.700W) synchronous motor on the NASA wind tunnel project to control a huge fan to generate wind speeds exceeding Mach 1, improving the reliability, efficiency and capacity of the NASA facility.

Ormen Lange Gas Pipeline Project: Starting in 2007, natural gas from the Ormen Lange offshore gas field will pass through the world’s longest undersea tunnel from Norway to the UK. The huge compressors used for natural gas transmission are driven by three 48MW MEGADRIVE-LCIs provided by ABB. The entire transmission system, including transformers and motors, passed the rigorous full-load test, and the product met satisfactory test requirements in all aspects.

Related product recommendations:

ABB 5SHX36L4520

ABB 5SHY35L4522

ABB 5SHX1960L0004 3BHL000390P0104

ABB 5SHX06F6004 3BHB003387R0101

ABB 5SHX1445H0001

ABB 3BHB018160R0001 5SHY4045L0001

ABB 5SHY3545L0010

ABB 5SHY3545L0010 3BHB013088R0001

ABB 5SHX1960L0004 3BHL000390P0104

ABB 3BHL000390P0104 & 3BHB003154R0101

ABB 5SHY35L4503 3BHB004692R0002

ABB 5SHX 1060H0003

ABB 3BHB020720R0002

ABB 5SHX2645L0004 5SXE04-0150

ABB 5SHY5045L0020

ABB 5SHX1960L0006 3BHB016120R0002

ABB 3bhb003230r0101 + 3bhl000392p0101

ABB 3BHB020538R0001 5SHX1060H0003

ABB 5SHY4045L0004 GVC736CE101

ABB 5SHY3545L0009 3BHB013085R0001

ABB 5SHY3545L0009 3BHB013085R0001

ABB 5SHY35L4520 5SXE10-0181 AC10272001R0101

ABB 5SHX1445H0001

ABB 3BHB012961R0001

ABB 5SHY3545L0009

ABB 5SHY3545L0014, 3BHE023784R0001

ABB 5SHY4045L0001 3BHB018162R0001

ABB 5SHX1445H0002 + 3BHL000387P0101

ABB 5SHX 1000H0003

ABB 5SHY3545L0014 GVC736CE101

More…

There are no reviews yet.