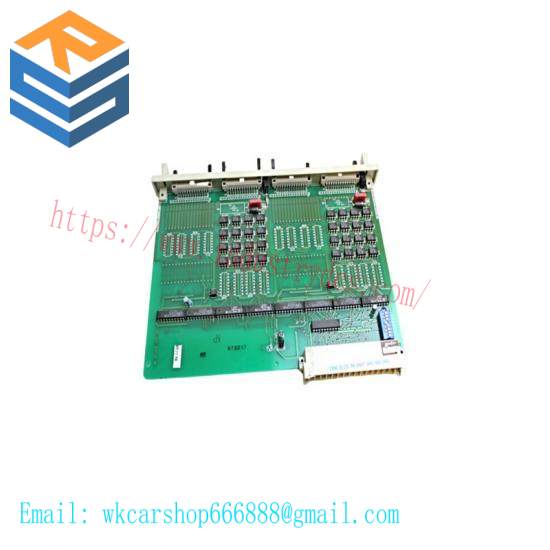

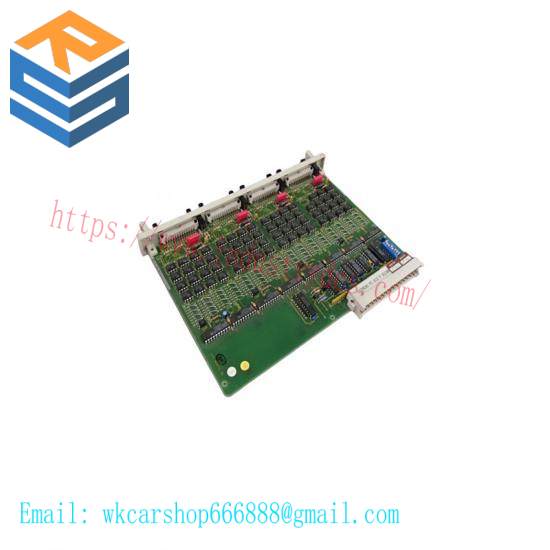

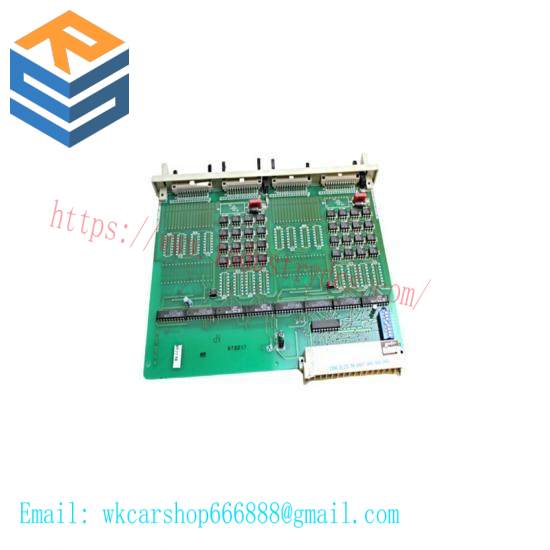

The UNS4681V511 3BHE004074R0511 Real-Time Accelerator (RTA) board is a high-performance hardware module designed by ABB for industrial automation and control systems, primarily designed to enhance the system’s real-time responsiveness and data processing speed.

Product Overview

Definition and Functionality

The Real-Time Accelerator (RTA) board is a dedicated hardware module that optimizes control algorithm execution efficiency, reduces latency, and ensures stable system operation within strict time constraints through technologies such as parallel processing and hardware acceleration.

Model UNS4681V511 3BHE004074R0511 : Developed by ABB for specific application scenarios (such as power electronics, motion control, and process automation), the RTA board is integrated into ABB control systems (such as 800xA, AC500, and UNITROL excitation systems).

Core Value

Improving real-time performance: Reduces the execution time of critical control tasks from milliseconds to microseconds, meeting highly dynamic response requirements (such as motor speed regulation and grid frequency regulation).

Reduce the main CPU load: Offload complex calculations (such as PID control and matrix operations) to the RTA board, freeing up main processor resources and improving overall system throughput.

II. Technical Features

Hardware Architecture

Processor Type: Utilizes FPGA (Field Programmable Gate Array) or dedicated ASIC chips to achieve hardware-level parallel computing.

Interface Design:

High-speed communication interfaces (such as PCIe, EtherCAT, and Real-Time Ethernet) enable seamless integration with the main control system.

Analog/digital I/O interfaces directly connect to sensors and actuators, reducing signal conversion latency.

Clock Accuracy: A high-precision clock source (such as GPS synchronization) ensures time synchronization error of <1μs between multiple devices.

Performance

Computational Latency: Typical control cycle time is ≤100μs, meeting the fast adjustment requirements of power electronic equipment (such as SVG and STATCOM).

Data Throughput: Supports millions of operations per second (such as floating-point operations and logical reasoning), adapting to complex model predictive control (MPC) scenarios.

Reliability: Industrial-grade design (operating temperature -40°C to +85°C), MTBF (mean time between failures) >100,000 hours.

Software Support

Development Environment: Compatible with ABB automation development tools (such as Automation Builder and Control Builder), supporting graphical programming and C/C++ code embedding.

Algorithm Library: Pre-installed common control algorithms (such as PID, fuzzy control, and neural networks), allowing users to quickly configure or customize them.

III. Typical Application Scenarios

Power Electronics Control

Flexible AC Transmission (FACTS): In SVCs (static VAR compensators) and STATCOMs (static synchronous compensators), the RTA board implements rapid reactive power regulation and mitigates grid voltage fluctuations.

High-Voltage Direct Current (HVDC): Used for converter valve control, ensuring stable DC voltage and current transmission.

Motion Control

High-Speed Motor Drive: In equipment such as rolling mills and printing presses, the RTA board implements high-precision speed/position closed-loop control, reducing mechanical vibration and noise.

Robot Control: Collaborates with multi-axis servo systems to achieve trajectory planning and dynamic compensation, improving robot motion smoothness.

Process Automation

Chemical Reactor Control: In high-temperature and high-pressure environments, the RTA board rapidly responds to temperature and pressure changes to prevent runaway reactions.

Boiler Combustion Optimization: By calculating the fuel/air ratio in real time, it reduces NOx emissions and improves combustion efficiency.

IV. Selection and Integration Key Points

Compatibility Verification

Confirm that the RTA board is compatible with the hardware interface (PCIe, EtherCAT) and software protocols (OPC UA, Modbus TCP) of the existing control system (such as ABB 800xA, AC500 PLC).

Check the power supply requirements (e.g., 12V/24V DC) to ensure they match the system power supply.

Performance Matching

Select the appropriate model based on the real-time requirements of the application scenario (e.g., control cycle, latency tolerance). For example:

UNS4681V511 3BHE004074R0511 Basic Edition: Suitable for conventional PID control, latency ≤ 500μs.

UNS4681V511 3BHE004074R0511 High-Performance Edition: Supports complex algorithms (such as MPC) with a latency of ≤100μs.

Redundant Design

In critical applications, it is recommended to configure dual RTA boards for redundancy. This allows for automatic failover through heartbeat detection, improving system availability.

V. Maintenance and Troubleshooting

Daily Inspection

Monitor the RTA board temperature (via system logs or LED indicators) to ensure proper heat dissipation (operating temperature <70°C).

Regularly check interface connections for loose connections to prevent communication interruptions caused by poor contact.

Common Troubleshooting

Symptom: RTA board not recognized or control delay increased.

Cause: Firmware version mismatch, hardware damage, communication line interference.

Solution: Upgrade the firmware to the latest version; replace a spare board for testing; and check the shield cable for proper grounding.

Spare Parts Management

Stock critical RTA boards to shorten troubleshooting time (MTTR <2 hours).

Record board serial numbers and replacement history for traceability and quality analysis.

Related product recommendations:

LDGRB-01 3BSE013177R1

3BHB015651P0001

DKTFM418B 3BHB015651P0001

3BHB009884R0021

S-073N 3BHB009884R0021

3BHL000986P0006

5SDF1045H0002

5SDF0860H0003

3BHE009681R0101

3BHB013088R0001

5SHY3545L0010

3BHB019265R0410

PPC907BE 3BHE024577R0101

PM865K01 3BSE031151R1

More……

There are no reviews yet.